If you don't measure it you can not control it. It is the result of careful planning, design, and execution.

Quality can not be inspected in after the fact. We can now control the process in order to control the quality.

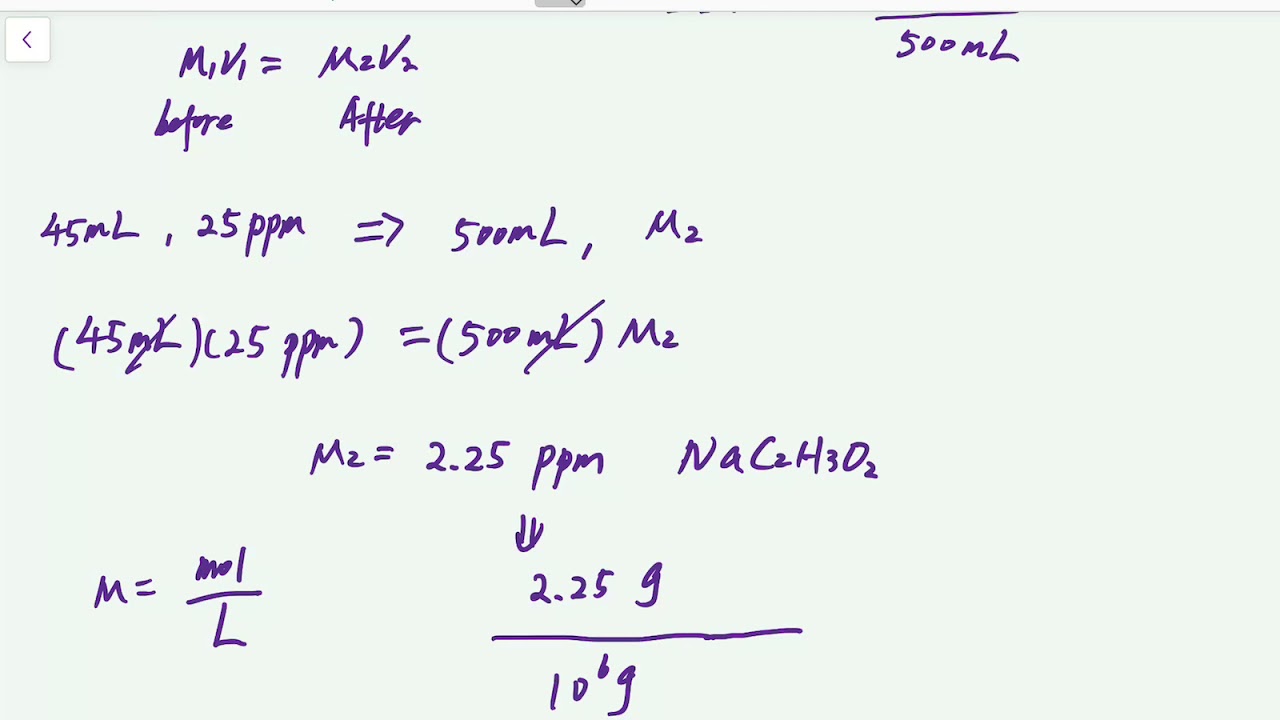

The monitoring and measurement systems we have today have paved the way for improved quality. Insanity is doing things the same way we've always done them and expecting different results. Impossible? Yes if you are still using the same manufacturing methods which were responsible for the 5 or 10% scrap you used to accept.Ī friend of mine had the following quotation on his wall: Way, one bad part per day! Notice I did not say one bad part per day per That means that you would be allowed 25 pieces for everyġ,000,000 pieces or 250 defective parts per year. Let's assume your customers requirementsĪre 25 PPM. Like most companies, your plant operates around 5 days a week, 50 weeks Say, you produce 10,000,000 parts per year for your customer. To calculate: For example, let's say you had 25 pieces defective in a shipment of 1,000 pieces. Now the rate for most automotive components is targeted at 25 PPM or 0.0025% There was a time when you were considered a pretty good supplier when your defect rate was less than 1%, (10,000 PPM), then the expectation was increased to 0.1% or 1,000 PPM. PPM (Parts per million) is a measurement used today by many customers to measure quality performance.ĭefinition: One PPM means one (defect or event) in a million or 1/1,000,000

0 kommentar(er)

0 kommentar(er)